|

|

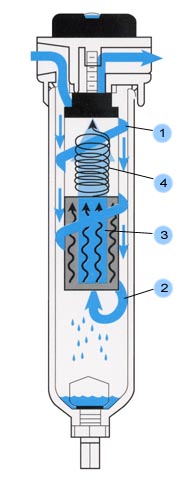

1. Centifugal Spin |

|

Bulk contamination water oil and dirt enter and are spun in circular manner as the air flows vertically downwards. This spinning action, which is naturally created by the

patented element design, forces the heavy particles outward where they contact the inside of the bowl and drain to the bottom. |

|

|

2. Inverse-Flow |

|

|

The patented inverse-flow process creates a condition where the air changes directions by 180 degrees from vertically downward to vertically upward. This process prevents the

re-entrainment of contamination which normally occurs. Contamination, which is flowing vertically downward, is not capable of reversing direction and must separate from the air flow, falling to the bottom of

the bowl. This separation effectively pre-filters the air of contaminants thereby extending the life of the filter element. |

|

|

3. Stainess Steel Element |

|

|

This first filter media which the pre-cleaned air enters is a deep bed of finely interwoven stainless steel mesh wires. These wires have an extremely striated outer surface and

will hold aerosols and liquid droplets which have survived the Inverse-Flow and Centrifugal Spin preocesses. These small droplets will collect on the wire media, forming larger droplets which will fall into

the drain area. This stage also filter oil and dirt to 3 micron with 99% efficiency. |

|

|

4. Friction Drying |

|

|

Consisting of interwoven cotton, polyester and stainless steel material, this final filter media captures sub-micron water droplets which have bypassed the stainless steel wire mesh. The cotton holds the water particles and allows them to re-enter the air stream as a harmless vapour. This stage also filters oil and dirt to 1 micron. |